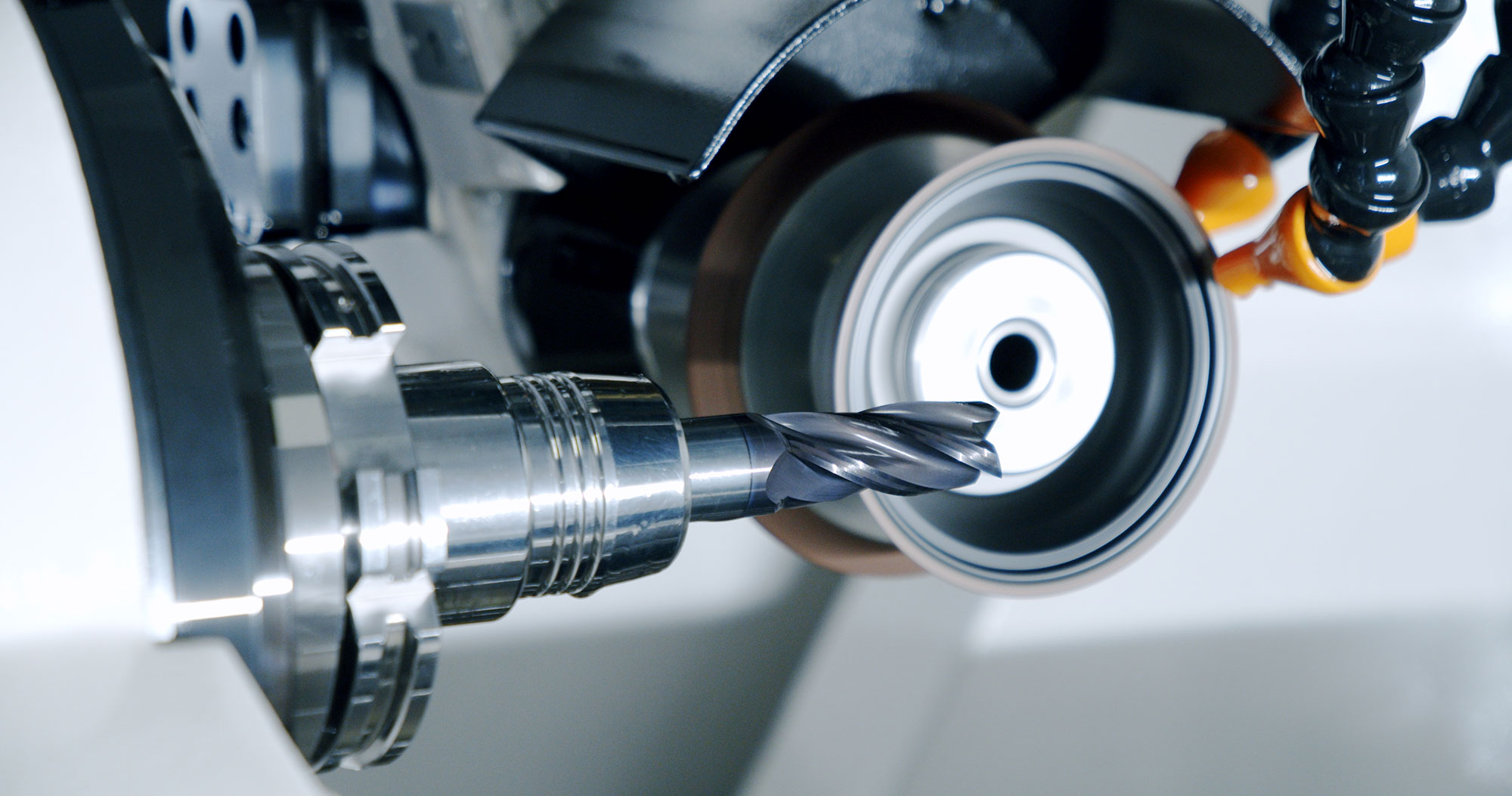

Our regrinding service ensure full reconditioning of tools so that they will work as if they were new. The regrinding process follows the same patterns used for production in order to recover the original geometry of tools. If necessary, and after they have gone through regrinding and quality control, the tools are coated to ensure wear resistance and optimal hardness. We use state-of-the-art machinery from leading brands like Vollmer, Walter, Akemat and Zoller.

WE REGRIND

Carbide-tipped circular saw blades

Carbide and high-speed steel drills

Carbide and high-speed steel milling cutters

Carbide and high-speed steel taps

Carbide and high-speed steel countersinks

WHY REGRINDING?

— It extends tool working life reducing production costs of machining processes.

— It helps reduce available tool stocks thanks to our short delivery times.

— It is a practical and simple process: customers just have to send their tools to AFILMUR, they will get them back ready for use.

— It results in good use of raw materials reducing its waste.